Encoder Couplings

Products

Flexible Disc Couplings

These couplings consist of a series of flexible discs, usually made of stainless steel, that connect the encoder shaft to the driven shaft. They provide high torsional stiffness, precision, and backlash-free transmission of torque, making them suitable for applications that require accurate position and motion control.

Oldham Couplings

Oldham couplings consist of three components – two hubs and a center disc. The center disc has tongue and groove slots that engage with the hubs, allowing for angular misalignment compensation. Oldham couplings are known for their simple design, low cost, and moderate torque transmission capabilities, making them suitable for a wide range of encoder applications.

Bellows Couplings

Bellows couplings utilize a thin-walled metal bellows to connect the encoder shaft to the driven shaft. They offer high torsional stiffness, zero backlash, and excellent compensation for angular, parallel, and axial misalignment. Bellows couplings are commonly used in applications that require high precision and low inertia, such as robotics and automation systems.

Beam Couplings

Beam couplings use a single or multiple helical-cut beams to connect the encoder shaft to the driven shaft. They provide high torsional stiffness and excellent compensation for angular, parallel, and axial misalignment. Beam couplings are often used in applications that require precise motion control, such as CNC machines and robotics.

Enhance the precision and reliability of your encoder system with our top-of-the-line encoder couplings,ensuring accurate and seamless motion control for a wide range of applications.

High torsional stiffness for accurate position and motion control.

1

Zero backlash transmission for precise and repeatable measurements.

1 - 3

Excellent compensation for angular, parallel, and axial misalignment.

2 - 20

Robust construction for durability and long-lasting performance.

1

Wide range of sizes and materials to suit various application requirements.

1 - 8

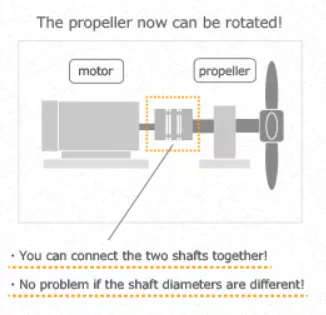

What is an encoder coupling?

Encoder Couplings attach an encoder shaft to another rotating shaft, protecting the encoder from shaft to shaft misalignment. In order for encoder couplings to work effectively, they need to be flexible and accurate. Without flexible coupling, the misalignment may cause friction, heat, vibration, and noise.

Frequent Questions and Answers

Is high or low coupling better?

- High coupling means that a change in one component affects many others, making the system complex, rigid, and fragile. Low coupling means that the components are loosely connected and can function independently, making the system simple, flexible, and robust.Is high or low coupling better?Is high or low coupling better?

How do I determine the correct size and type of encoder coupling for my application?

- To determine the correct size and type of encoder coupling, consider factors such as torque requirements, shaft diameter, speed, and misalignment compensation needed. Consulting with coupling manufacturers or referring to their product catalogs can help in selecting the appropriate coupling that meets the specific demands of your application.

Can encoder couplings accommodate different types of misalignment?

- Yes, encoder couplings are designed to accommodate various types of misalignment, including angular, parallel, and axial misalignment. Different types of couplings offer different levels of misalignment compensation. By choosing the right coupling with adequate flexibility and design features, you can ensure optimal performance and longevity of your encoder system.

Our Factory

What is coupling and why it is used?

A coupling is a mechanical element part that connects two shafts together to accurately transmit the power from the drive side to the driven side while absorbing the mounting error (misalignment), etc.